Managing Heat

29.07.2024 23:55:33 Yorum Yok Görüntülenme4 min read

Preparations for Next Moonwalk Simulations Underway (and Underwater)

Science in Space: July 2024

This time of year, managing heat is on everyone’s mind. Especially now, as May 2024 marked a full year of record-high monthly temperatures – an unprecedented streak, according to scientists from NASA’s Goddard Institute for Space Studies in New York.

NASA experts analyze data from thousands of land-, sea-, and sky-based instruments to calculate Earth’s global temperature. Knowing how hot it is helps scientists, health care workers, and public officials plan for and respond to the heat’s effects on people and infrastructure.

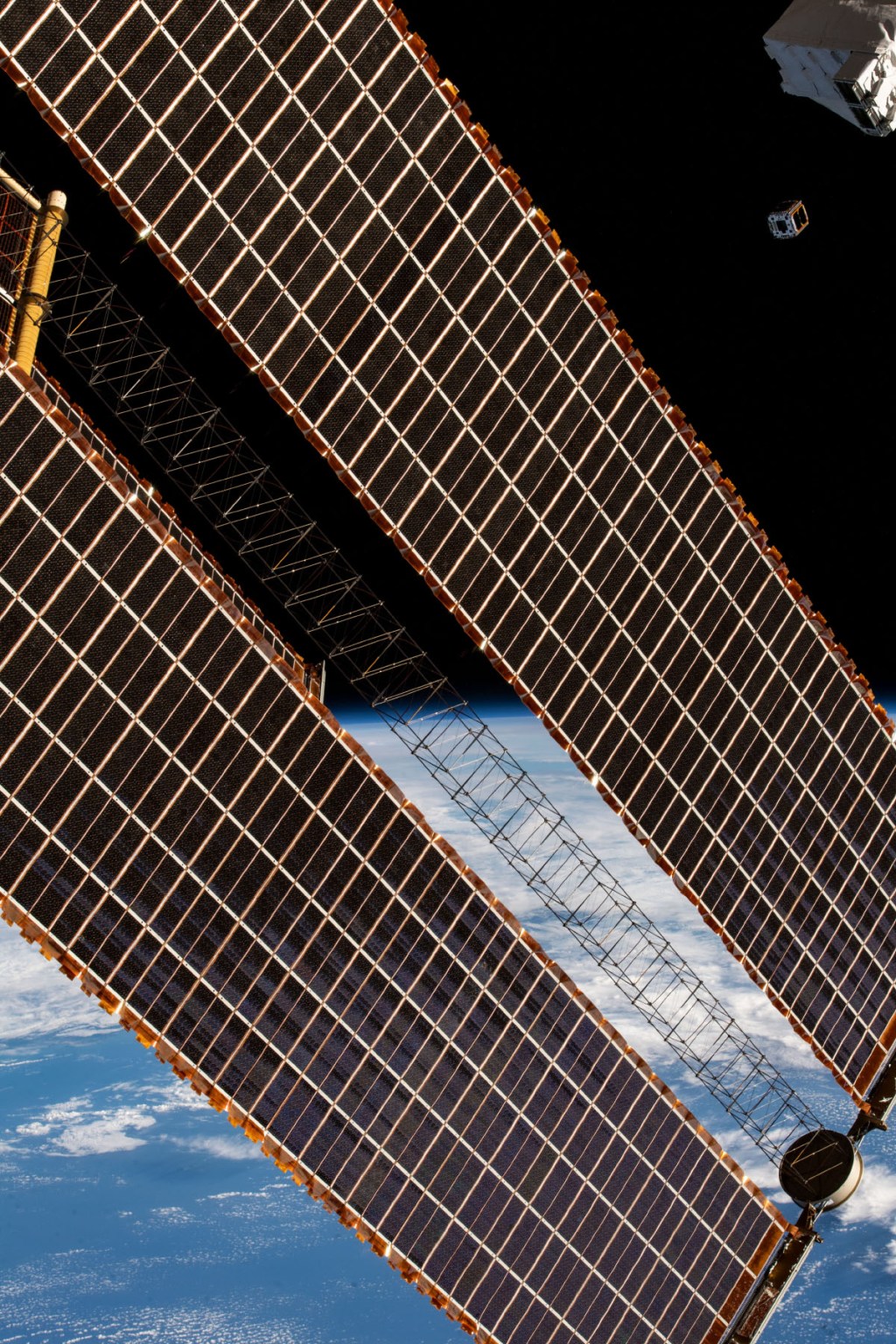

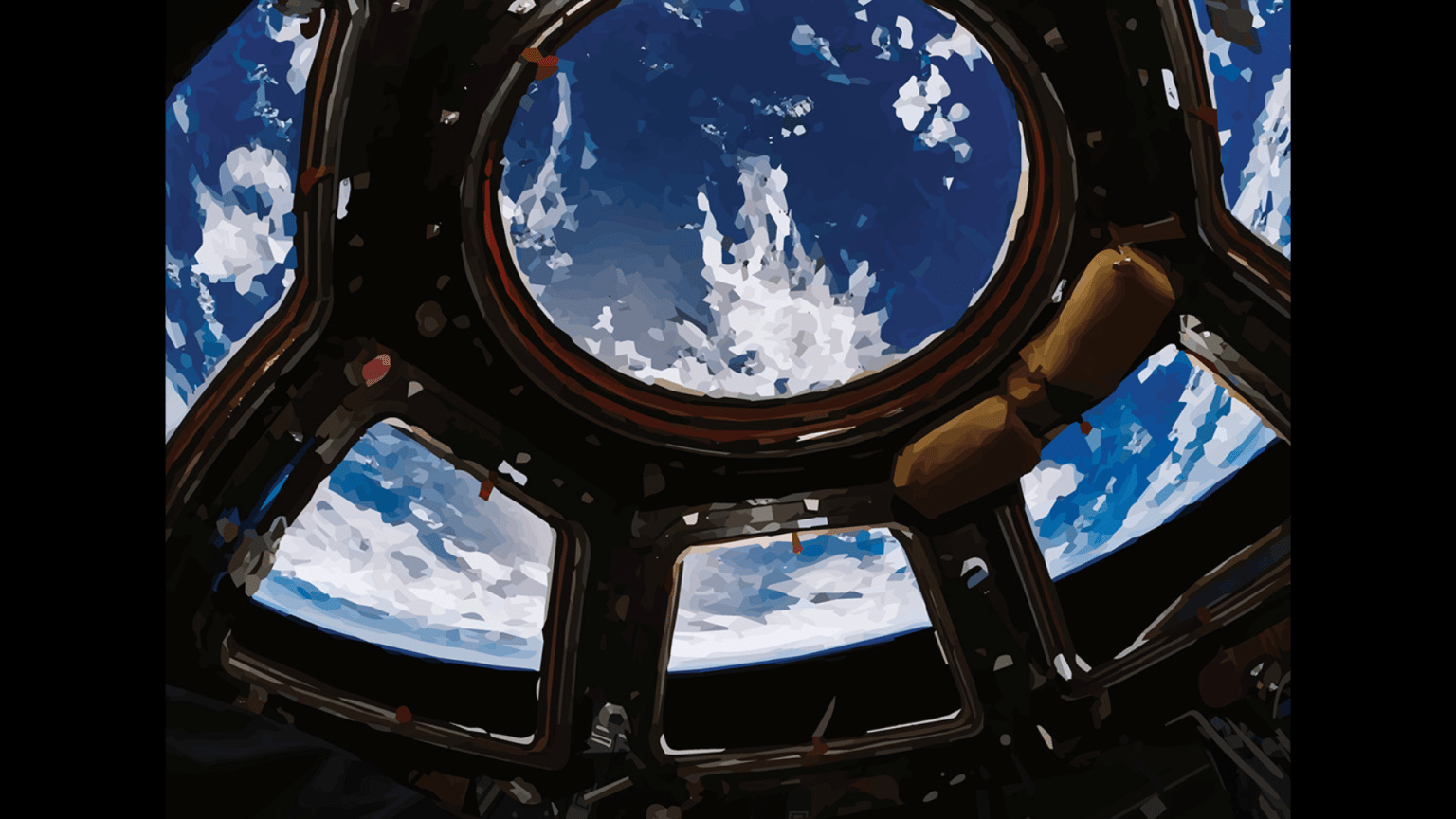

Crew members on the International Space Station deal with a different type of heat – that generated by electronics, life support systems, and other equipment. Managing this heat is essential to the operation of the spacecraft and the health and safety of its occupants.

Taking out the heat

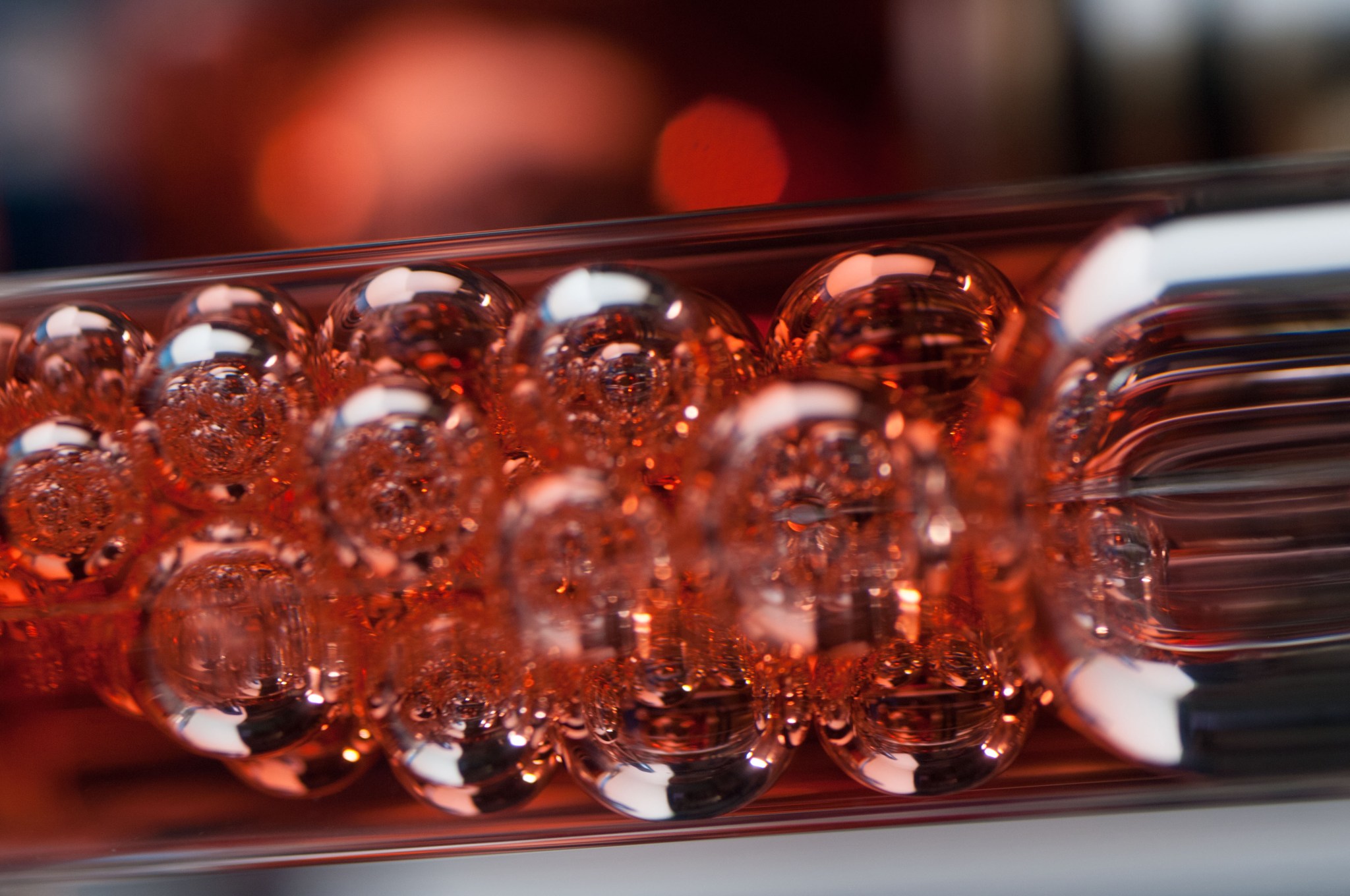

Packed bed reactors (PBRs) are structures packed with beads of different materials to increase contact between a liquid and a gas flowing through them. They are widely used for many applications, including thermal control or heat management, life support systems, and water filtration and offer low power consumption, compact size, and reliability. Packed Bed Reactor Experiment: Water Recovery Series (PBRE-WRS) continues evaluation of how microgravity affects the performance of different packing media. The material used and the shape and size of the beads all contribute to the effectiveness of heat exchange in a PBR. This investigation could inform the design and operation of these systems in microgravity and on the Moon and Mars and lead to improvements in this technology for applications on Earth such as water purification and cooling systems.

Previous investigations, PBRE and PBRE-2, provided fundamental understanding of simultaneous gas and liquid flow through PBRs in microgravity. This improved understanding helps to support development of more efficient and lightweight thermal management and life support systems for future missions.

Boiling heat away

As electronic devices add more features, they generate more heat, which becomes increasingly challenging to remove. Flow boiling is a method of thermal management that uses this heat to boil a moving liquid and generate vapor bubbles that lift the heat from the surface, then change back to a liquid via condensation. But using boiling for heat management is less efficient in microgravity because, in the absence of buoyancy, bubbles grow larger and remain near the surface.

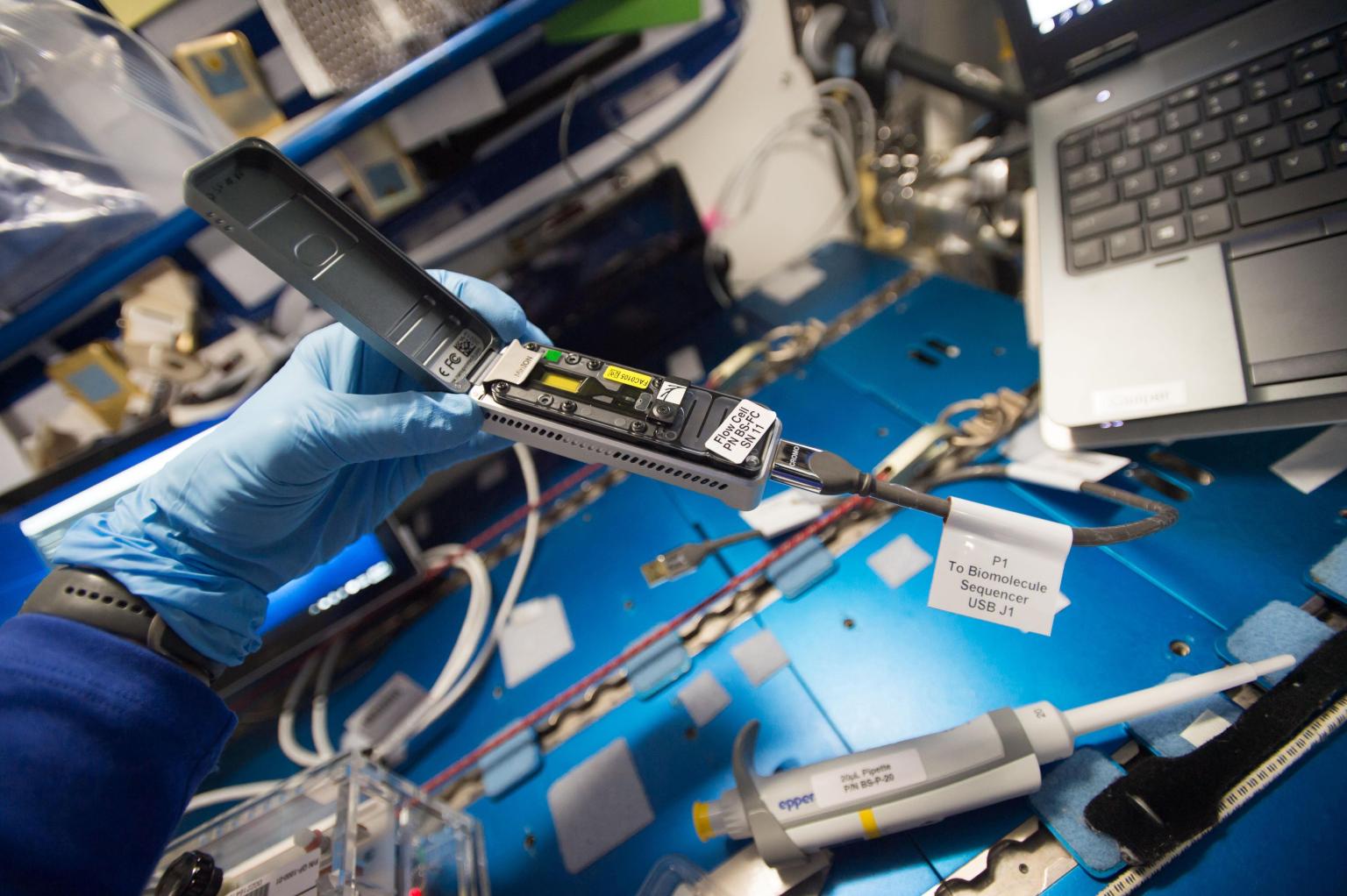

The Flow Boiling and Condensation Experiment (FBCE) tested a model for a flow boiling and condensation facility for the space station. Researchers identified important factors affecting this process in microgravity and how they differ from those on Earth. The findings could help researchers identify ways to improve the operation of these systems in microgravity.

This research also led to development of an artificial neural network (ANN) trained on data from the FBCE experiment to predict heat flow and transfer for use in the design and analysis of thermal systems. ANNs are a type of artificial intelligence made of computational units similar to neurons in the nervous systems of living things.

The PFMI-ASCENT investigation found that adding microscopic teeth or rachets to a surface caused more bubbles to form and increased the transfer of heat. This finding helps further improve flow boiling systems used to remove heat from electronics in space.

Going with the flow

Liquids behave differently in space than they do on Earth. Capillary Flow Experiment-2 studied wetting, or a liquid’s ability to spread across a surface, in different container shapes in microgravity. Results showed that models adequately predict liquid flow for various container shapes. These predictions support improved design of systems that process liquids aboard spacecraft, including systems for thermal control.

Melissa Gaskill

International Space Station Research Communications Team

Search this database of scientific experiments to learn more about those mentioned in this article.